Indrayani Nagar Road, MIDC, Bhosari +91 9371032929 nexuspipefitting@gmail.com

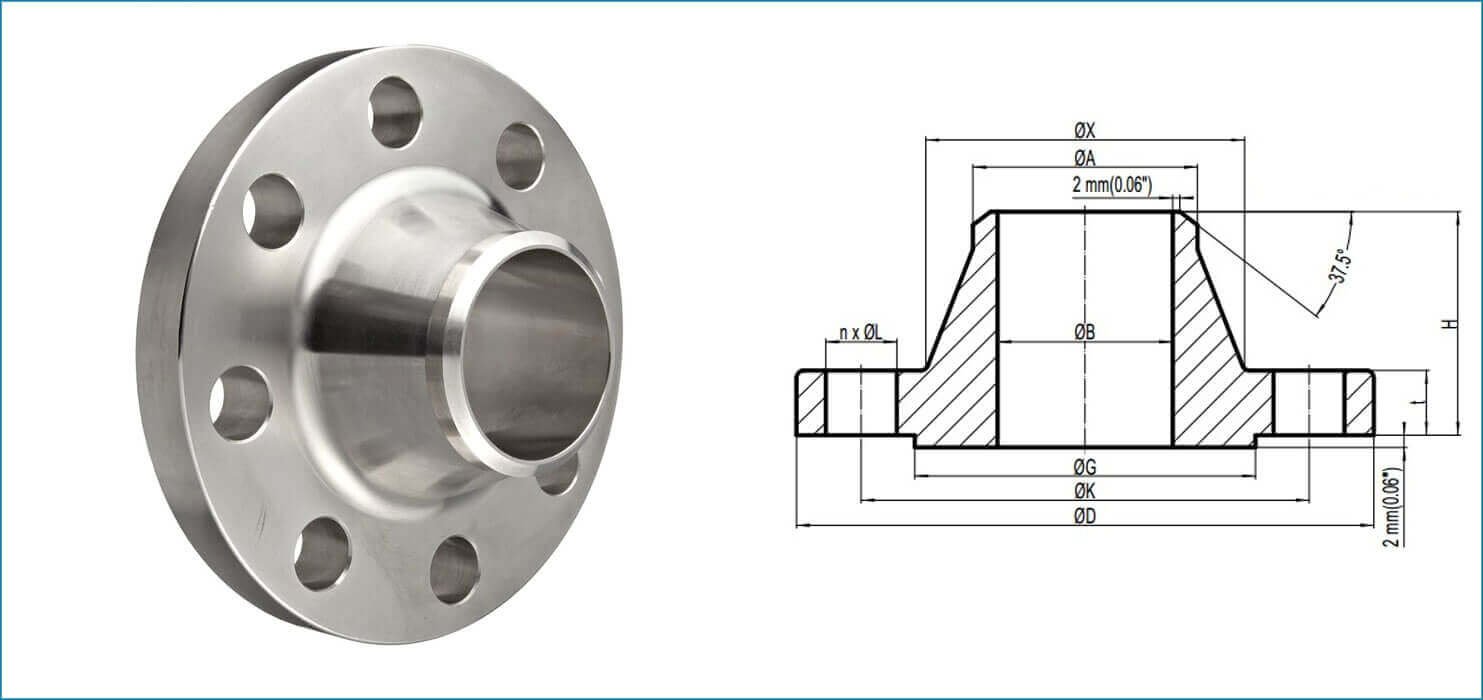

Weld neck flanges, often referred to as "butt-weld flanges", are one of the most common types of flanges used in piping systems. They are designed to be welded to a pipe or other components, offering a smooth, reinforced connection that can handle high-pressure applications. The flange has a long, tapered neck that is welded to the pipe, providing strength and a high resistance to stress and fatigue. These flanges are frequently used in critical piping systems that require high integrity and are subject to significant pressure.

Advantages of Weld Neck Flanges: